New Capable and Compact Mass Spectrometry Technologies

Recent challenges have exemplified the continuing need for powerful and versatile analytical solutions.

From virus detection to bloodborne pathogen screening, mass spec has proven invaluable for a wide variety of applications. Here we look at a few new compact and capable solutions, as well as the concepts these technologies are based upon.

The MBT Sepsityper Kit US IVD from Bruker

Bruker announced the launch of the MBT Sepsityper Kit US IVD at the turn of the 2021 new year. Designed for rapid and affordable identification of microorganisms from positive blood cultures, the technology is based upon the trusted MALDI Biotyper CA System.

What is MALDI Biotyper (MBT) technology? MBT is the result of years of Matrix-assisted laser desorption time-of-flight (MALDI-TOF) mass spectrometry innovation from Bruker. Designed to enable rapid and definitive identification in clinical microbiology labs, MBT addressed the laborious and sub-optimal methods that traditionally challenged this environment. A faster and less expensive alternative to DNA sequencing, the MBT technology has been optimized for microbial identification and is now a leading solution in clinical microbiology labs. Shown right is the MALDI Biotyper Sirius instrument.

What is MALDI Biotyper (MBT) technology? MBT is the result of years of Matrix-assisted laser desorption time-of-flight (MALDI-TOF) mass spectrometry innovation from Bruker. Designed to enable rapid and definitive identification in clinical microbiology labs, MBT addressed the laborious and sub-optimal methods that traditionally challenged this environment. A faster and less expensive alternative to DNA sequencing, the MBT technology has been optimized for microbial identification and is now a leading solution in clinical microbiology labs. Shown right is the MALDI Biotyper Sirius instrument.

How does it work? The MALDI Biotyper (MBT) identifies the molecular fingerprint of each microorganism type by analyzing the collection of abundant proteins from each sample and matching the MALDI spectra with a database of FDA-cleared reference spectra. In short, the MBT uses clinical protein fingerprinting techniques. MBT data shown right.

What is the MBT CA system? This version of the MBT was granted US FDA clearance under Section 510(k) for the identification of gram-negative and gram-positive bacteria, anaerobic bacteria and yeast, cultures from human specimens. It is a qualitative in vitro diagnostic device for use with additional indicators to aid clinical diagnosis of infections in patients.

The new MBT Sepsityper Kit US IVD is capable of identifying over 425 microbial species from positive blood cultures. The workflow includes a rapid 30-minute time-to-result, as opposed to 24 hours for traditional plate culturing. Most importantly, the new technology offers a rapid diagnostic solution for bacteremia-induced sepsis, a high mortality and morbidity rate condition which affects millions of patients per year.

The Waters RADIAN ASAP System

At the tail end of 2020, Waters announced the new RADIAN ASAP System, a novel direct mass detector designed for non-mass spectrometry experts.

What sets this system apart? The RADIAN ASAP is intended to offer fast and accurate analysis of solids and liquids with minimal sample prep. The system’s simplified and rapid mode of operation, along with it’s compact and power design features, enable widespread adoption across a multitude of industries. The Waters RADIAN ASAP instrument is shown below.

What user pain points are addressed? Lab professionals are being tasked with ever-broadening and time-sensitive duties in the lab. Regardless of the industry, there is a growing need for analytical technologies that are both accurate and powerful while remaining accessible to a wide range of operators and experience levels. The RADIAN ASAP system overcomes several of the barriers to entry by providing seamless integration into labs and enabling users with minimal LC-MS training to achieve high-quality results.

What user pain points are addressed? Lab professionals are being tasked with ever-broadening and time-sensitive duties in the lab. Regardless of the industry, there is a growing need for analytical technologies that are both accurate and powerful while remaining accessible to a wide range of operators and experience levels. The RADIAN ASAP system overcomes several of the barriers to entry by providing seamless integration into labs and enabling users with minimal LC-MS training to achieve high-quality results.

How does the RADIAN ASAP system work? Based upon proven single quadrupole technology, this mass spec detector is interfaced with a dedicated Atmospheric Solids Analysis Probe (ASAP) source. Unlike typical Electrospray Ionization (ESI) sources, the sample can be readily ionized and guided into the instrument without the need for low vacuum. This cuts down significantly on the complexity and the costs—not to mention the potential user interferences—that are associated with ESI-based LC-MS systems. Perhaps more importantly, the system does not rely on a liquid chromatography (LC) separation upstream of mass-charge detection, reducing time and complexity to an even greater extent.

The new RADIAN ASAP technology is well-suited as a tool for categoric screening and compound identification. A few notable applications include fit-for-purpose methods for pharmaceutical process monitoring, forensic screening for illicit drugs, and adulterant testing in food safety. The system is also useful for academic labs as a tool for teaching and method development.

The Coated Blade Spray (CBS) technology from Restek

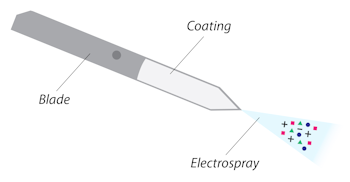

Designed to facilitate faster analysis of the growing influx of samples in the lab, Restek recently announced the new Coated Blade Spray (CBS) technology for rapid screening applications.

What is CBS technology? The coated blade spray is an easy-to-use sample preparation device, which allows direct coupling to the mass spec, permitting fast analysis of samples taken directly from the source specimen. The ability to interface directly with the mass spec means the LC separation step is eliminated, providing qualitive results for a multitude of rapid screening applications.

How does the coated blade spray work? The concept is based around the principles of selective partitioning of analytes of interest in water, solutions, or semi-solid samples.

How does the coated blade spray work? The concept is based around the principles of selective partitioning of analytes of interest in water, solutions, or semi-solid samples.

- A special partitioning coating is fixed over a stainless-steel substrate (the blade), which allows analytes to quickly partition from samples while preventing large, matrix-related compounds from adhering to the blade.

- The substrate is simply laid in contact or submerged in the sample.

- After washing the analyte-laden blade in solvent, high-voltage is applied and analyte molecules are ionized for mass spec analysis.

- The blade is machined and coated to facilitate the effective ionization of the partitioned analytes prior to mass spec analysis.

- The stainless-steel conducts the applied high-voltage, and the pointed tip functions to assist formation of the electrospray cone.

- When affixed to the instrument, the tip of the blade is precisely positioned to allow entry of molecular ions into the mass analyzer.

What are the applications of CBS? A novel technology, the one immediate application is for rapid screening of compounds. However, the CBS technology is currently being tested to interface with various models and configurations of mass spec devices – potentially extending it’s use to biomarker, liquid biopsy, and other related applications.

Outlook

Newly emerging, capable and compact mass spec technologies are intended to tackle the following areas:

- Reducing the resources required for a given application.

- Removing unnecessary components and workflow complexity.

- Extending access to a wider range of industries and users.

The instruments we’ve reviewed above are designed to address these points:

- The MBT Sepsityper Kit US IVD offers a rapid and definitive diagnostic solution to the critical challenge of bacterial-sepsis.

- The RADIAN ASAP System avoids unnecessary components, while streamlining workflows and performance for a variety of users.

- The Coated Blade Spray technology enables rapid sample screening with the potential for a wide array of important applications.